I.1.

INTRODUCTION

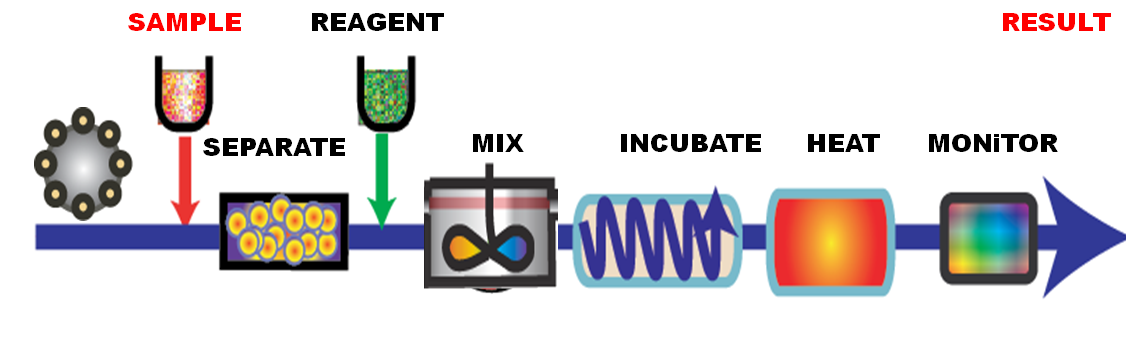

Automation of reagent based assays, transformed the traditional “beaker chemistry” from labor intensive time consuming task, into computer assisted microfluidic interface that yields desired information in real time. The transport of sample trough a number of operations needed to obtain a result can be automated in two ways, in the batch mode or in the flow mode.

Batch processing is based on the classical approach, designed at the time, when, trough quantitative analysis, chemistry became a science.. In batch mode, each sample to be analyzed is assigned a container, within which the steps of a desired assay are being performed.

The modern version of a beaker is a microwell (typically 99-well format), while manual sample and reagent metering, as well as other mechanical manipulations, are carried out by robotics.. The main advantage of batch approach is the parallel processing, which allows the sampling frequency to be virtually independent of the rate of chemical reactions involved. Thus, high throughput screening, needed in drug discovery, is exclusively carried out in parallel, within a micro well format.

Flow processing is characterized by its versatility and ease of automation, as the apparatus often comprises only two mechanical components, a pump and a valve. Samples are processed in an enclosed tubular conduit, thus being protected from an outside environment. Throughout the years the flow systems were downscaled from milliliter to micro and even nano liter scale. The flow mode is suitable to automate separations, including gas diffusion, to handle suspensions and filtration, and is compatible with a very wide range of detection techniques.

Fluidic manipulations are the best choice for automated handling of liquid samples since the individual operations of an assay protocol are linked by a flowing carrier stream.

From Beaker to Microfluidics

Applied analytical chemistry is

the art of optimized transport.

Bo Karlberg